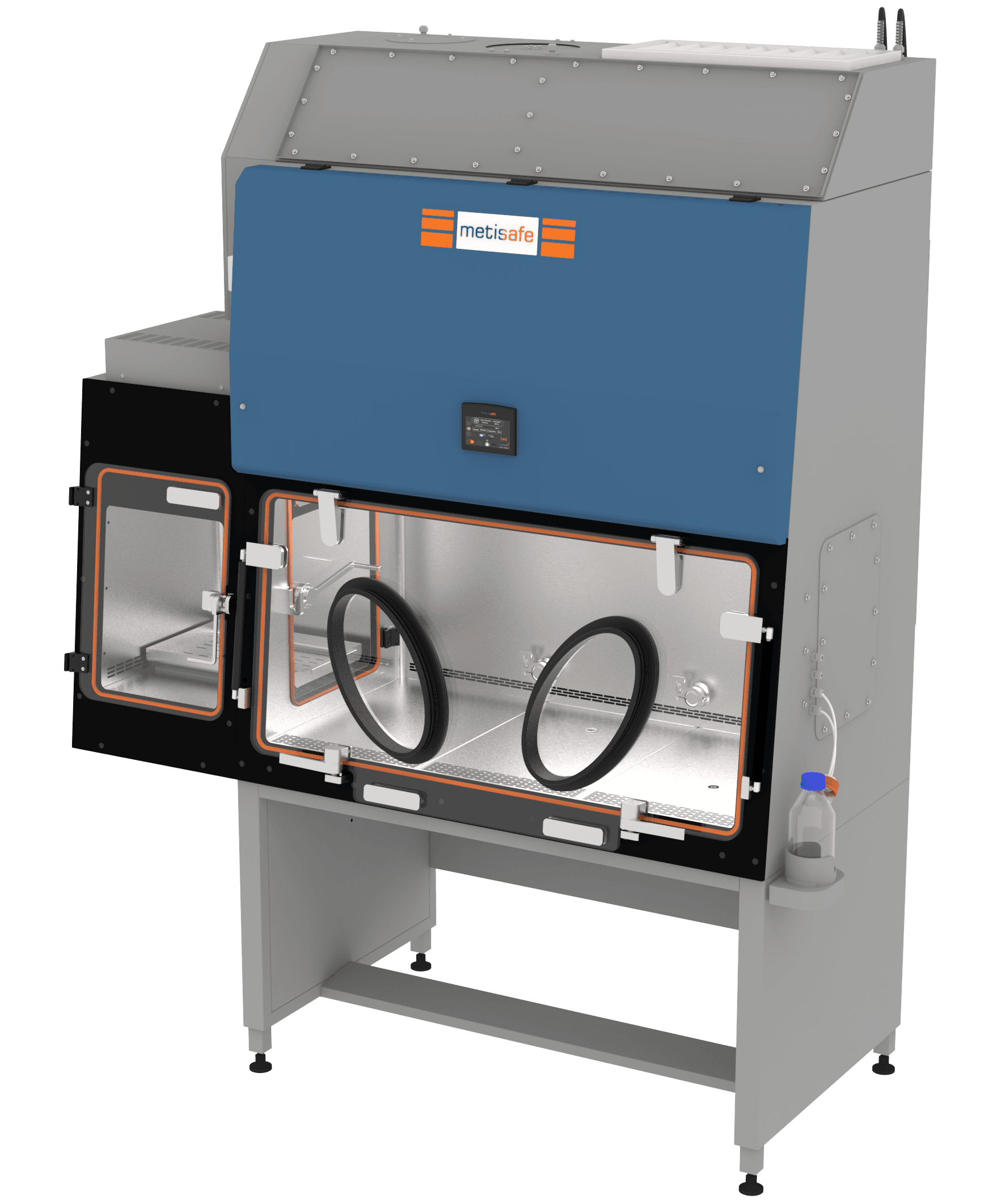

Sterilite Test Isolator - C Series

Isolators work under principles of particle filtration, air recirculation and keeping work chamber at positive or negative pressure. In positive pressure isolators, 90% (±%5) of total internal air is recirculated passing through main HEPA/ULPA filter located at work zone top. The rest of the air is exhausted after passing through HEPA/ ULPA filter located at the top of the cabinet. Negative pressure isolators exhaust total cabinet air completely to outer atmosphere without recirculation after passing through main filters . Pre/HEPA filtered room air is intaken by top of the cabinet and pass-box provides the work area protecting the work zone under ISO-5 class laminar airflow. In addition to primary air barrier accomplished by within the working zone double wall negative plenum design of the Metisafe cabinet prevents particle escape to surroundings and zero leakage is ensured

Main Body and Design Features

- Sealed main body covered with antibacterial electrostatic paint on stainless steel

- <7° angle sloped front panel for work comfort and increased working chamber vision

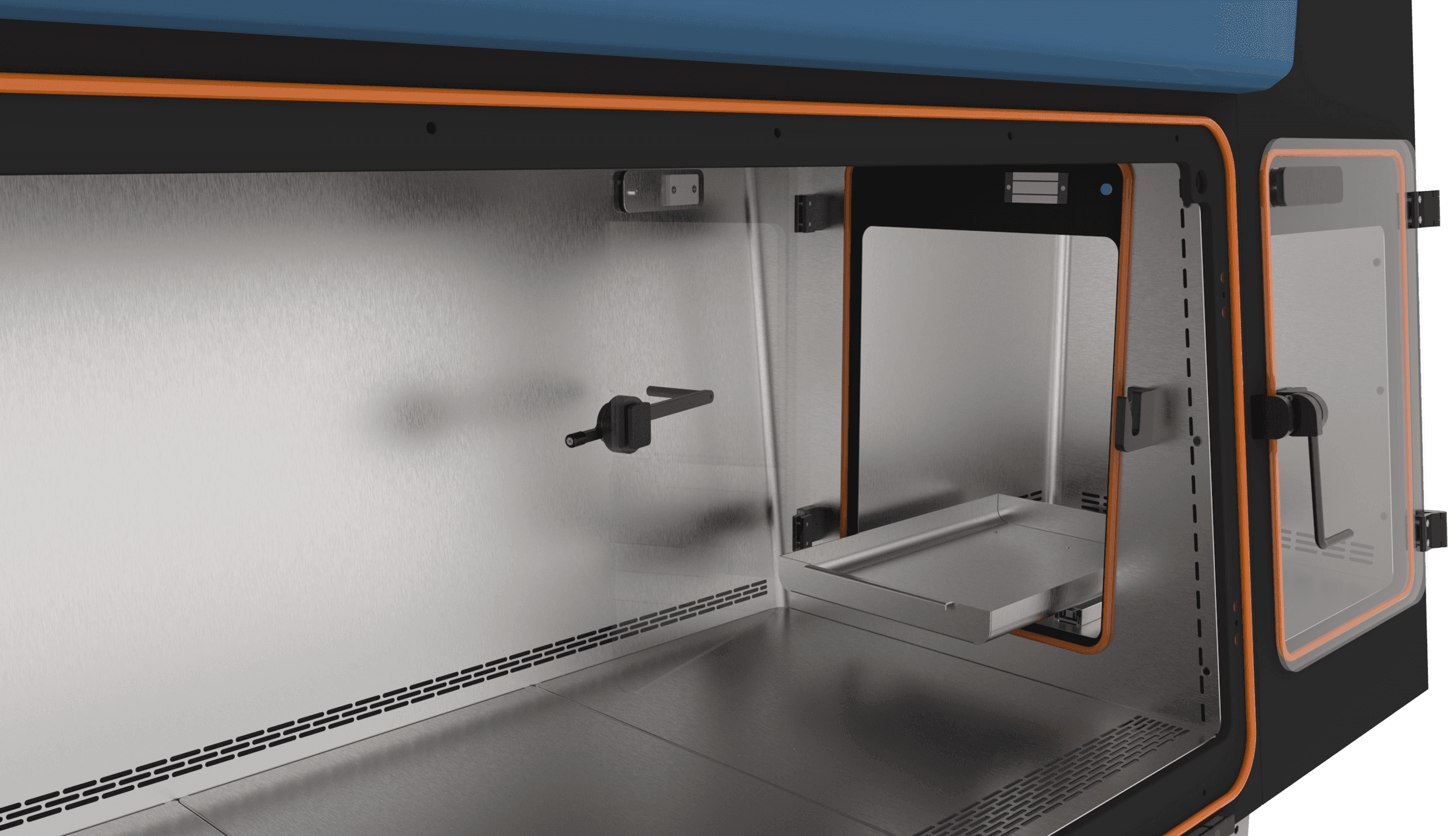

- Isolated automation systems from work chambers

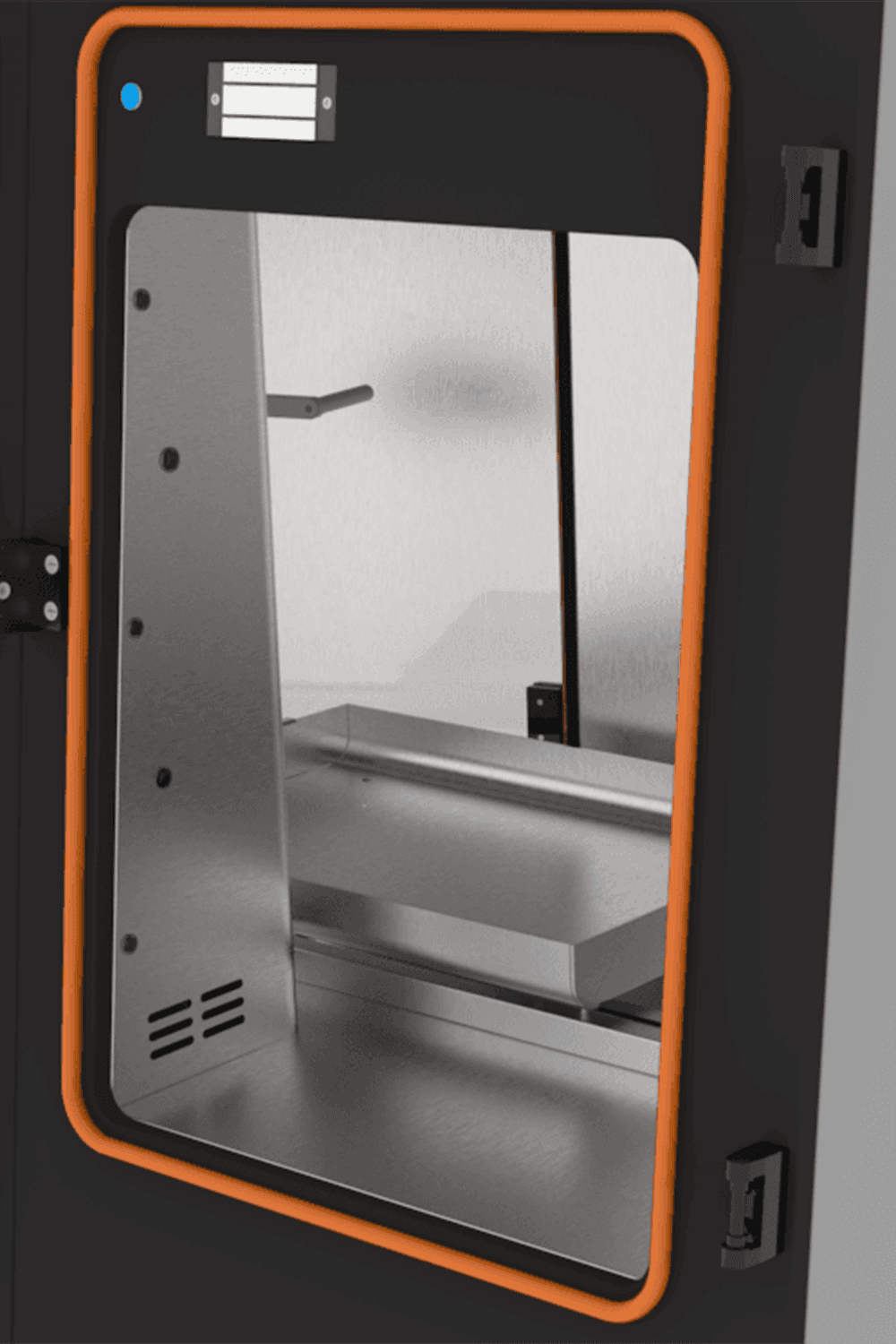

- Interlocked ISO-5 class dynamic pass-box with sliding load tray

- UV resistant safe front glass & radiused cornered pass-boox door glasses

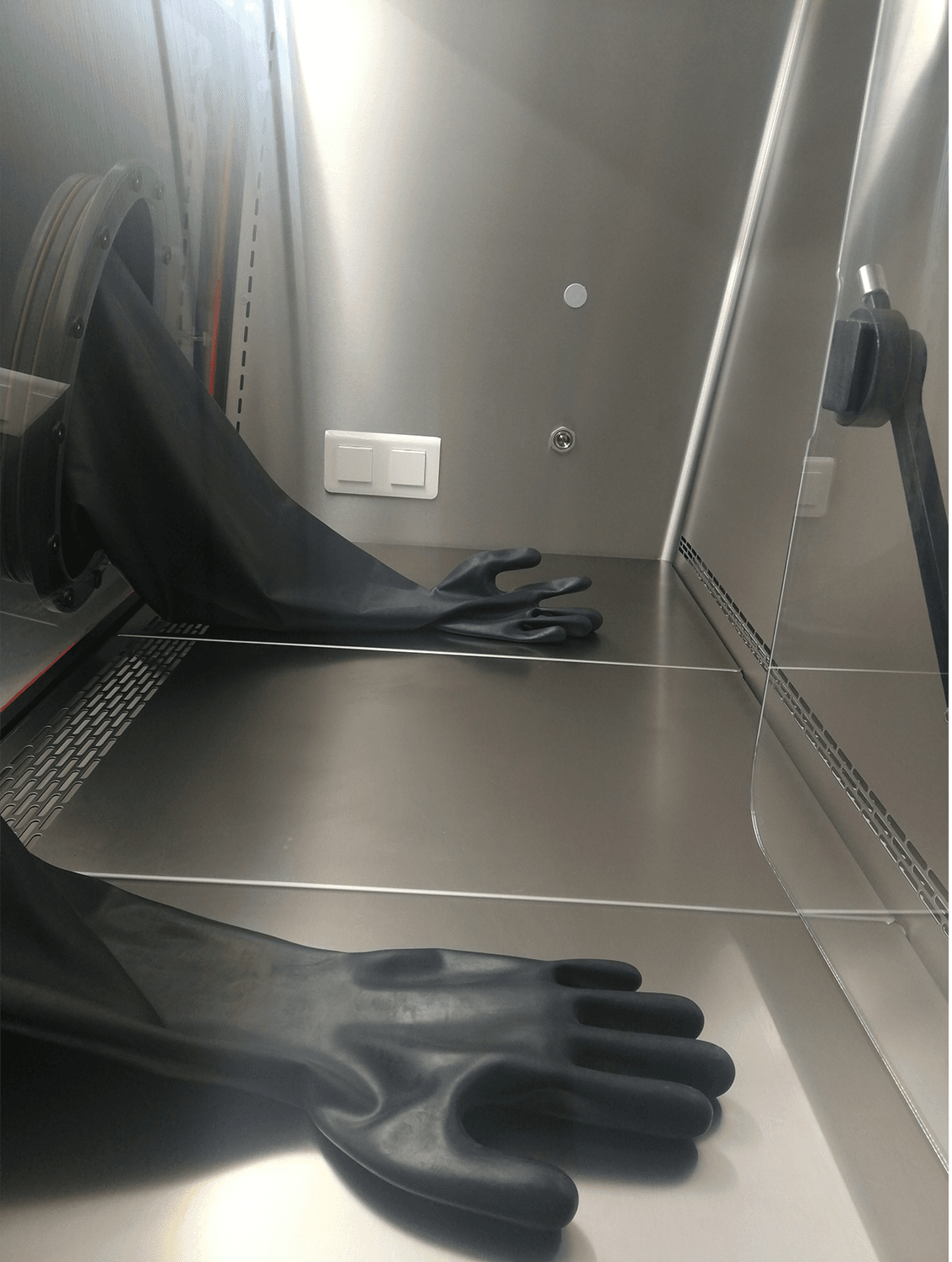

- Leakproof 0,6 > mm chemical resistant gloves

Microprocessor Control Unit

- Work chamber temperature and humidity rates

- Audible visual alarm button and temporary mute

- Single button start full automatic decontamination and process follow-up screens

- UV and illumination running times

- System running times

- Alarm status information

- Device on/off button

- Standby operation option

- Illumination level adjustment

- Filter change periods

- Filter integrity status

- Work chamber pressure value

- Date and time information

- Key lock system

Audial & Visual Alarm parameters

- Unproper pressure warning

- System ready/not-ready warning

- Service need warning

- Manual alarm cancel button

- Filter/lamps replacement warning

Decontamination System

- Full automatic decontamination process working parallel with work chamber temparature and humidity level

- Integrated H2O2 pulverization

- Sensitive H2O2 measurement

- Timer controlled efficient UV disinfection

Quality and Certificates

- CE

- ISO14644 Cleanroom Class Conformity

- ISO9001-2015 Quality Management Certificate

- EN61010 Electrical & Electronic Safety Conformity

- Validation Guarantee of accredited test organization

Optionals

- MOP.ADI Adjustable Illumunation

- MOP.HTS Humidity/Temperature Sensor

- MOP.PPR Process Parameter Recording System

- MOP.RES Remote Access

- MOP.FLT.ULP ULPA Filter

- MOP.PMS Particle Measure System

- MOP.WCS Working Cabinet Suspension Apparatus (IV Bar)

1250x620x695

1980x900x1735

1371x805x745

481x685x998

840 mm

H14 HEPA, 0,3 μm particle %99.995< filtration efficiency

EU4

304 Stainless Steel

316 Stainless Steel

2

< 56 dB(A)

850 – 1250 Lux

1555x620x695

2285x900x1735

1676x805x745

481x685x998

840 mm

H14 HEPA, 0,3 μm particle %99.995< filtration efficiency

EU4

304 Stainless Steel

316 Stainless Steel

3

< 56 dB(A)

850 – 1250 Lux