Class IIA BSC - C Series

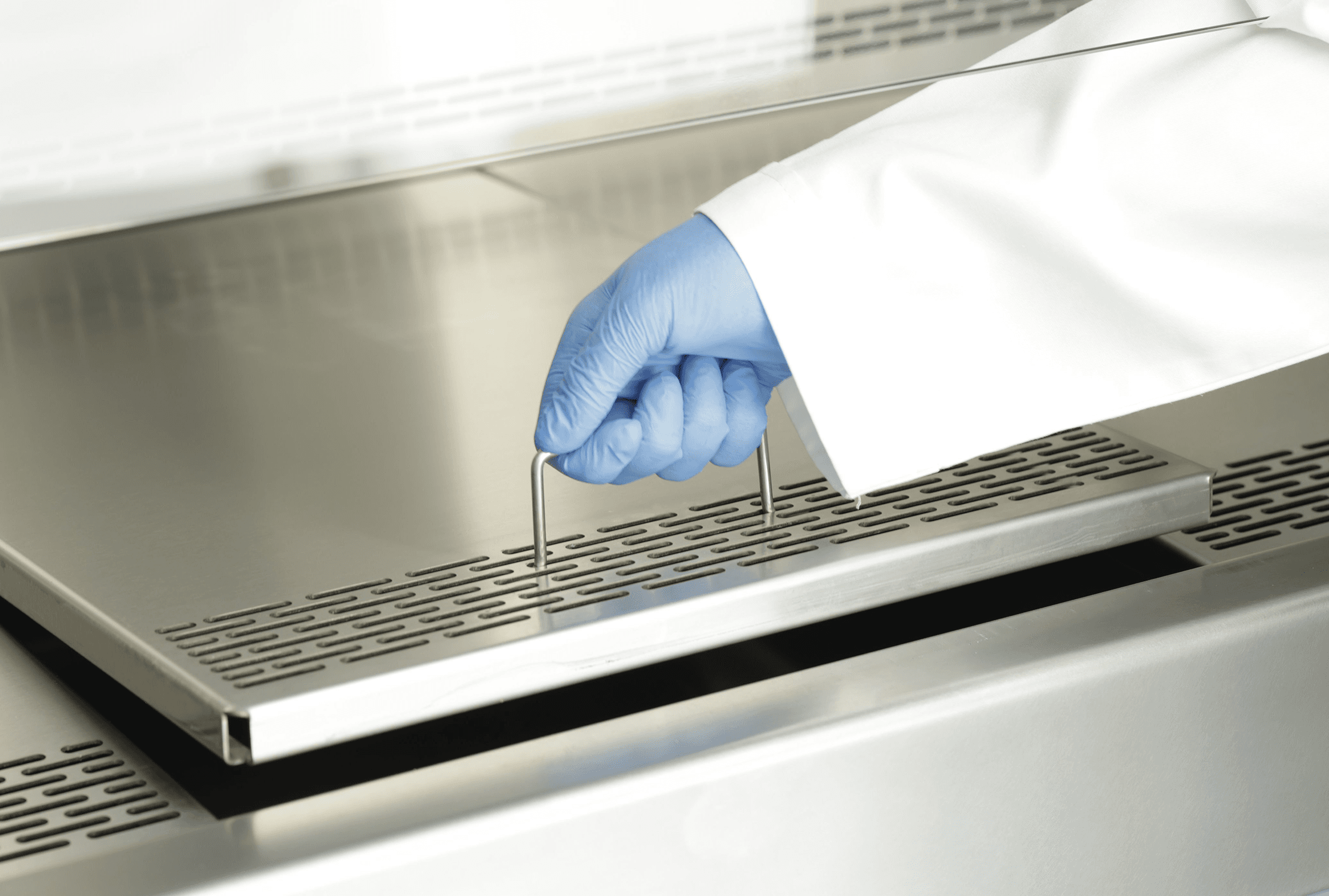

Metisafe® Biological Safety Cabinets recirculate 70% (± %5) of the device’s total air. After passing through the main HEPA/ULPA filter, the clean air flows down to the work chamber. The 30% (± %5) of the total air is exhausted out of the cabin after passing through the exhaust HEPA filter at the top of the device. The indoor environment’s intaken air is passed through the air grills in the front section of the workbench and directed to the fan unit. Those air barriers prevent the reach of dirty indoor air into the workbench. Both intaken and recirculated total air inside the device is collected in the fan section. Then it passes through the, main HEPA filter and laminarizator, and protects the work material by providing ISO- 5 cleanliness class laminar airflow. The primary air barrier occurs in the work chamber and the negative plenum structure surrounding it. The air in the cabin is prevented from reaching the user, including possible accidents, and a zero leakage work station is provided.

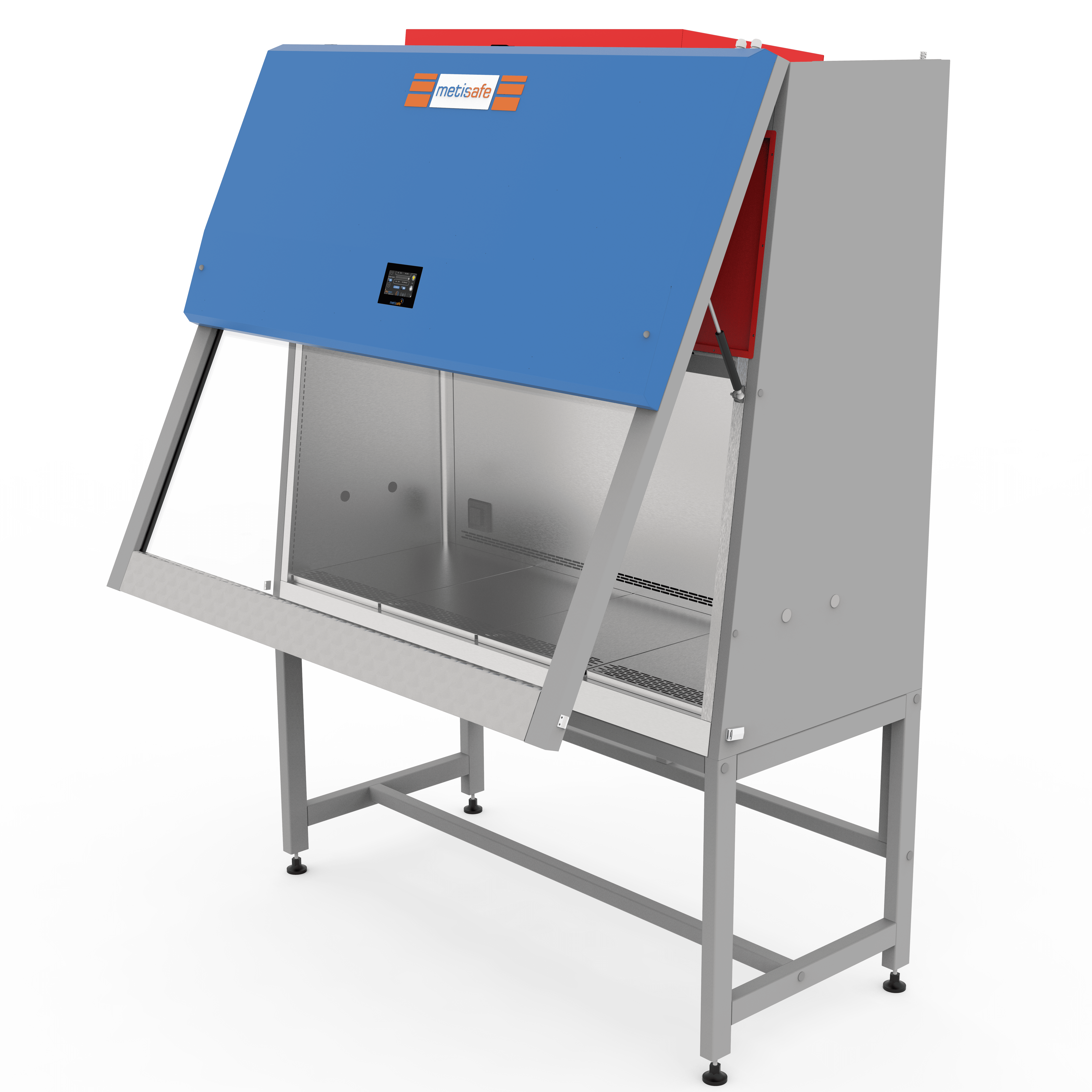

Main Body and Design Features

- Main body from antibacterial electrostatic paint coated on steel

- <7° angle back sloped front panel for work comfort and increased working chamber vision

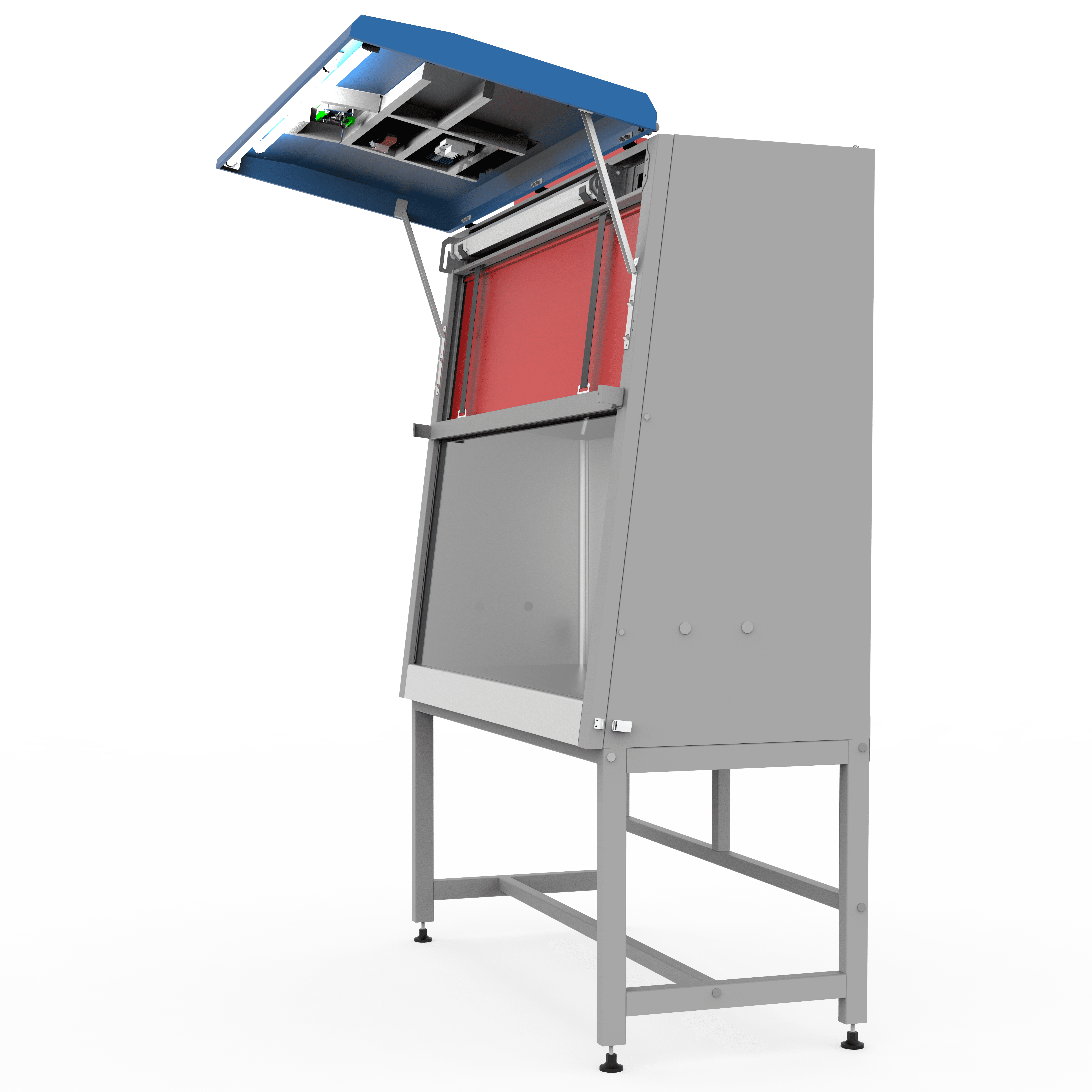

- 26° Openable front panel for easy working chamber cleaning

- Easy reachable electronic control & electrical part located inside at front panel isolated from work chamber

- UV resistant glass

Microprocessor Control Unit

- Password protected user interface

- Device on/off button

- Standby/Normal modes operation indicator

- Motorized front window level adjustment and one-button automatic front window level adjustment

- UV and illumination lamp On/Off buttons

- Automatic switch to Standby mode and UV lamp operation when the windshield is closed

- User interface password change

- Password protected technical service maintenance/calibration

- Date and time information

- Downflow/Inflow Air velocity rate

- Fan working capacity

- Fan working diagram

- UV lamp timer setting

- Cabinet, UV and illumination running times

Audio-Visual Warning System

- Audible visual alarm button and temporary mute

- Improper front window position warning

- Improper air velocity warning

- Filter and UV lamp replacement warning

- Technical service maintenance warning

Quality And Certifications

- CE

- Biological Safety Cabinets EN12469

- ISO9001-2015 Quality Management Certificate

- ISO14644 Cleanroom Class Compatibility

- EN61010 Electric and Electronic Safety Compatibility

- Accredited Testing Institution Validation Guarantee

Optionals

- MOP.ADI Adjustable Illumunation

- MOP. FWS Front Window Motion Safety System

- MOP.HTS Humidity/Temperature Sensor

- MOP.RES Remote Access

- MOP.CFL Carbon Filter

- MOP.FLT.EU4 Pre-Filter

- MOP.CFL.EU4 Active Carbon Impregnated Pre-filter

- MOP.FLT.ULP ULPA Filter

- MOP.MIE Microscope Entegration

- MOP.PMS Particle Measure System

- MOP.BWT Precision Balance with Vibration Damping Weighing Table

- MOP.WCS Working Cabinet Suspension Apparatus (IV Bar)

- MOP.MDS Manuel Decontamination System

- MOP.SDS Semi-Automatic Decontamination System

- MOP.CCP Canopy Connection

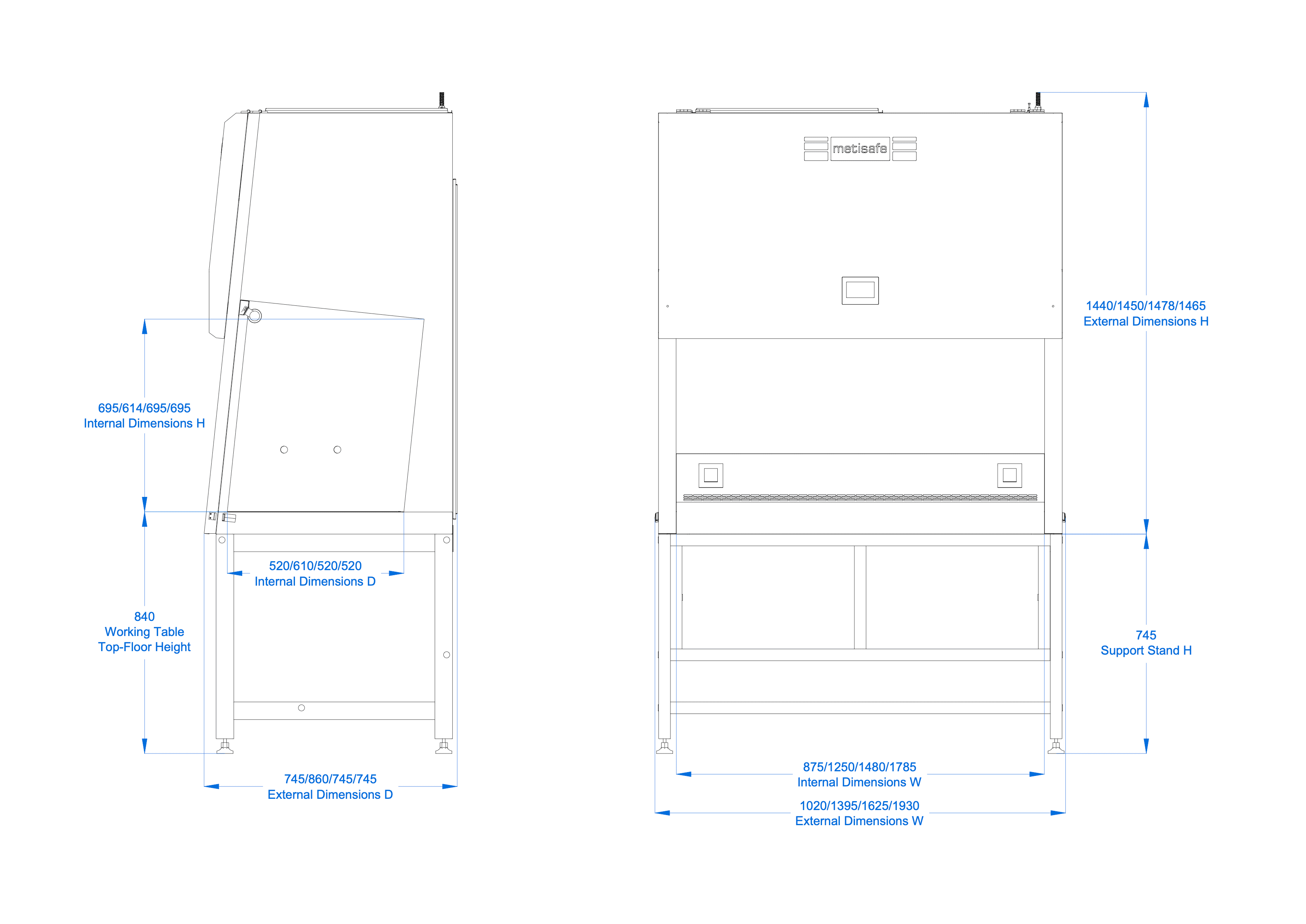

875x520x695

1020x745x1440

996x702x745

840 mm

≥ 0.40 m/s

0.25 - 0.50 m/s

H14 HEPA, 0,3 µm paticle %99.995 < filtration efficiency

304 Stainless Steel

316 Stainless Steel

≤ 65 dB

≥750 Lux

1250x610x614

1395x860x1450

1371x810x745

840 mm

≥ 0.40 m/s

0.25 - 0.50 m/s

H14 HEPA, 0,3 µm paticle %99.995 < filtration efficiency

304 Stainless Steel

316 Stainless Steel

≤ 65 dB

≥750 Lux

1480x520x695

1625x745x1478

1601x702x745

840 mm

≥ 0.40 m/s

0.25 - 0.50 m/s

H14 HEPA, 0,3 µm paticle %99.995 < filtration efficiency

304 Stainless Steel

316 Stainless Steel

≤ 65 dB

≥750 Lux

1785x520x695

1930x745x1465

1906x702x745

840 mm

≥ 0.40 m/s

0.25 - 0.50 m/s

H14 HEPA, 0,3 µm paticle %99.995 < filtration efficiency

304 Stainless Steel

316 Stainless Steel

≤ 65 dB

≥750 Lux

MSC-IIA-C Series Dimensions