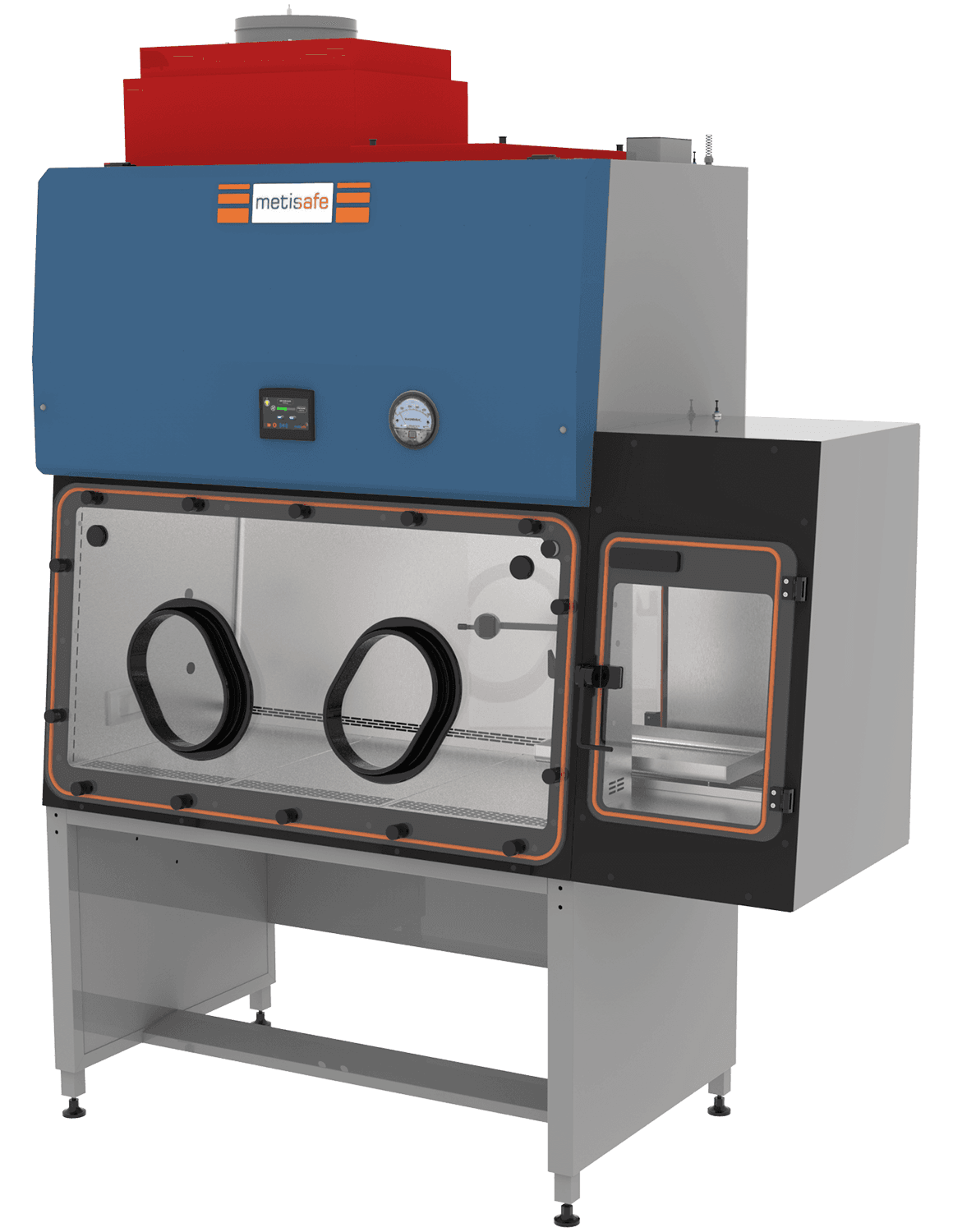

Class III BSC

Metisafe Class III BSC works under principles with fresh air supply taken from the indoor environment to the work chamber and pass-box through pre/HEPA filtration. Exhausting of contaminated cabinet air to the outer atmosphere after HEPA filtration also protects the environment. That airflow pattern of BSC Class III provides safe work with biological risk group 3/4 agents and also with cytotoxic gas & materials if assembled with optional carbon filters. Total air in the work chamber is fully purged to the exhaust air ducts without recirculation. Exhausting to the outer atmosphere is accomplished by the help of an endpoint blower fan. Controlled air exhausting keeps work chamber and cabinet under negative pressure. In addition to the primary air-barrier accomplished by negative pressure within the work zones, double-wall negative plenum design of the Metisafe BSCs prevents particle escape to surroundings and zero leakage is ensured.

Main Body and Design Features

- Sealed main body covered with antibacterial electrostatic paint on steel,

- <7° tilted front panel for increased operating cabin visibility and ergonomic working comfort

- Electronic control panel protected by exclusion from the work chamber

- UV resistant glass

- Air-tight glove ports air-tight glove ports

Microprocessor Control Unit

- Password protected user interface

- Device on/off button

- Standby/Normal modes button

- UV and illumination lamp On/Off buttons

- UV lamp operating while in Standby mode

- User interface password change

- Password protected technical service maintenance/calibration

- Date and time information

- Downflow Air velocity rate

- Fan working capacity

- Fan working diagram

- UV lamp timer setting

- Cabinet, UV and pre-filter running times

- Pressure value

Audio-Visual Warning System

- Audible visual alarm button and temporary mute

- Exhaust fan error warning

- Pressure warning

- Improper air velocity warning

- Filter, pre-filter and UV lamp replacement warning

- Front window open warning

- Technical service maintenance warning

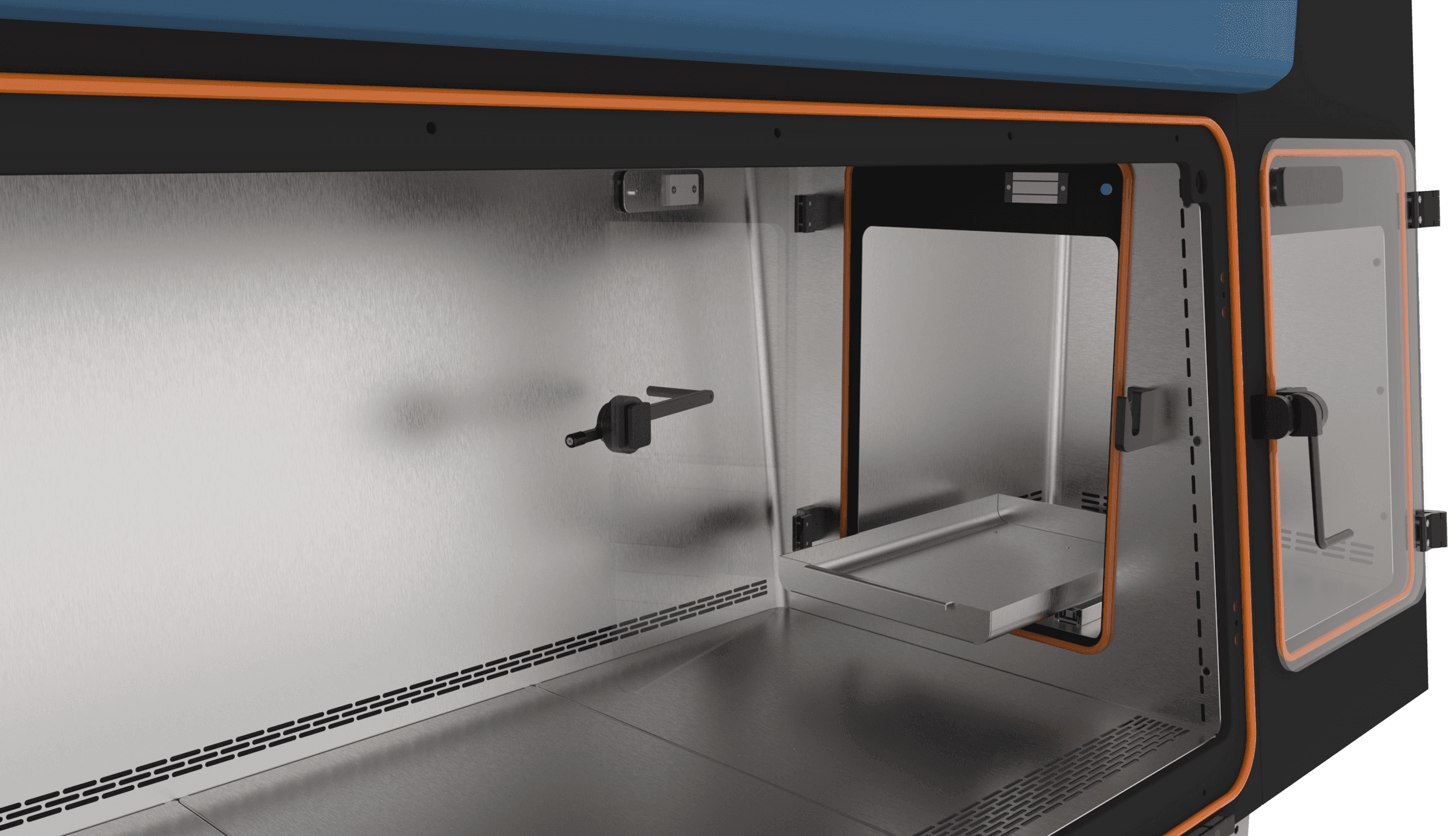

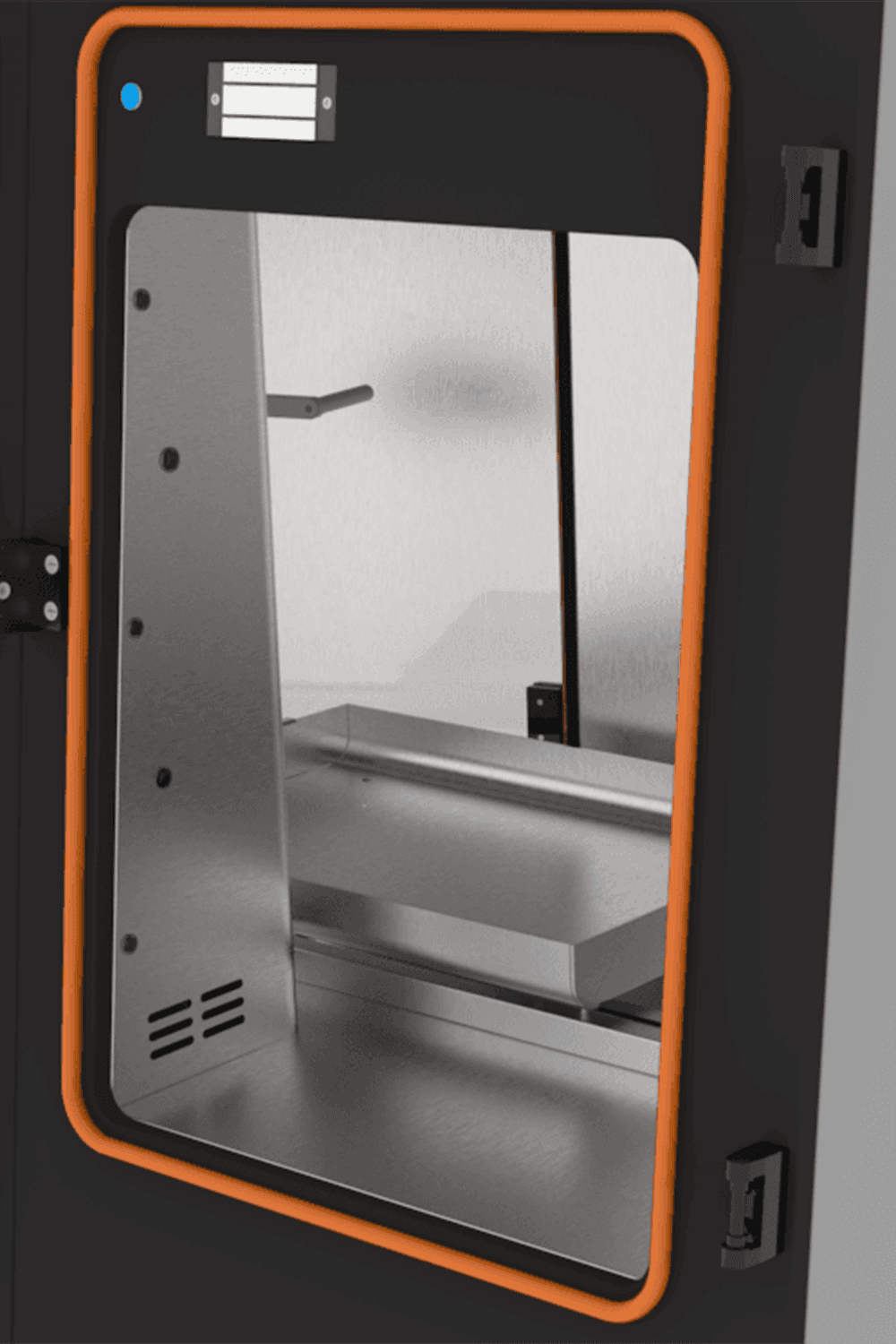

Active Pass-Box

- Electromagnetic inter-lock system

- Stainless steel inner surface with wide angle radiused corners

- Increased safety with rounded corner tempered glass lids

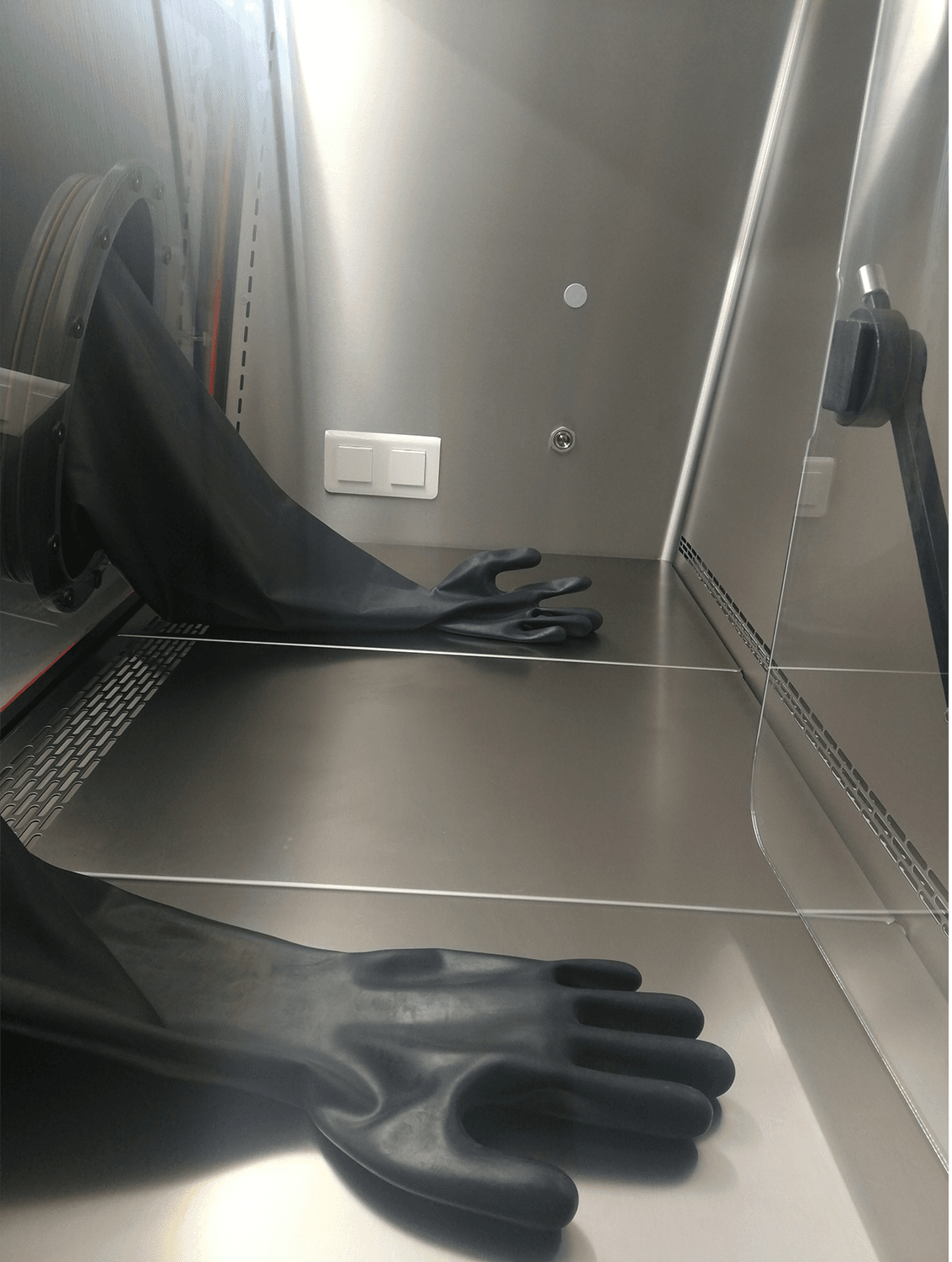

Glove

- Chemical or disinfection resistant

- High impermeability

- Good mechanical properties

- Resistant to ozone or UV rays

- Flexible handling and operation

- Long sleeve or Sleeve/Glove system options

Quality And Certifications

- CE

- ISO9001-2015 Quality Management Certificate

- ISO14644 Cleanroom Class Compatibility

- EN61010 Electric and Electronic Safety Compatibility

- Accredited Testing Institution Validation Guarantee

Optionals

- MOP.ADI Adjustable Illumunation

- MOP.HTS Humidity/Temperature Sensor

- MOP.PPR Process Parameter Recording System

- MOP.RES Remote Access

- MOP.CFL Carbon Filter

- MOP.CFL.EU4 Active Carbon Impregnated Pre-filter

- MOP.FLT.ULP ULPA Filter

- MOP.PMS Particle Measure System

- MOP.BWT Precision Balance with Vibration Damping Weighing Table

- MOP.WCS Working Cabinet Suspension Apparatus (IV Bar)

- MOP.MDS Manuel Decontamination System

- MOP.SDS Semi-Automatic Decontamination System

- MOP.FDS Fully Automatic Decontamination System

1250x620x695

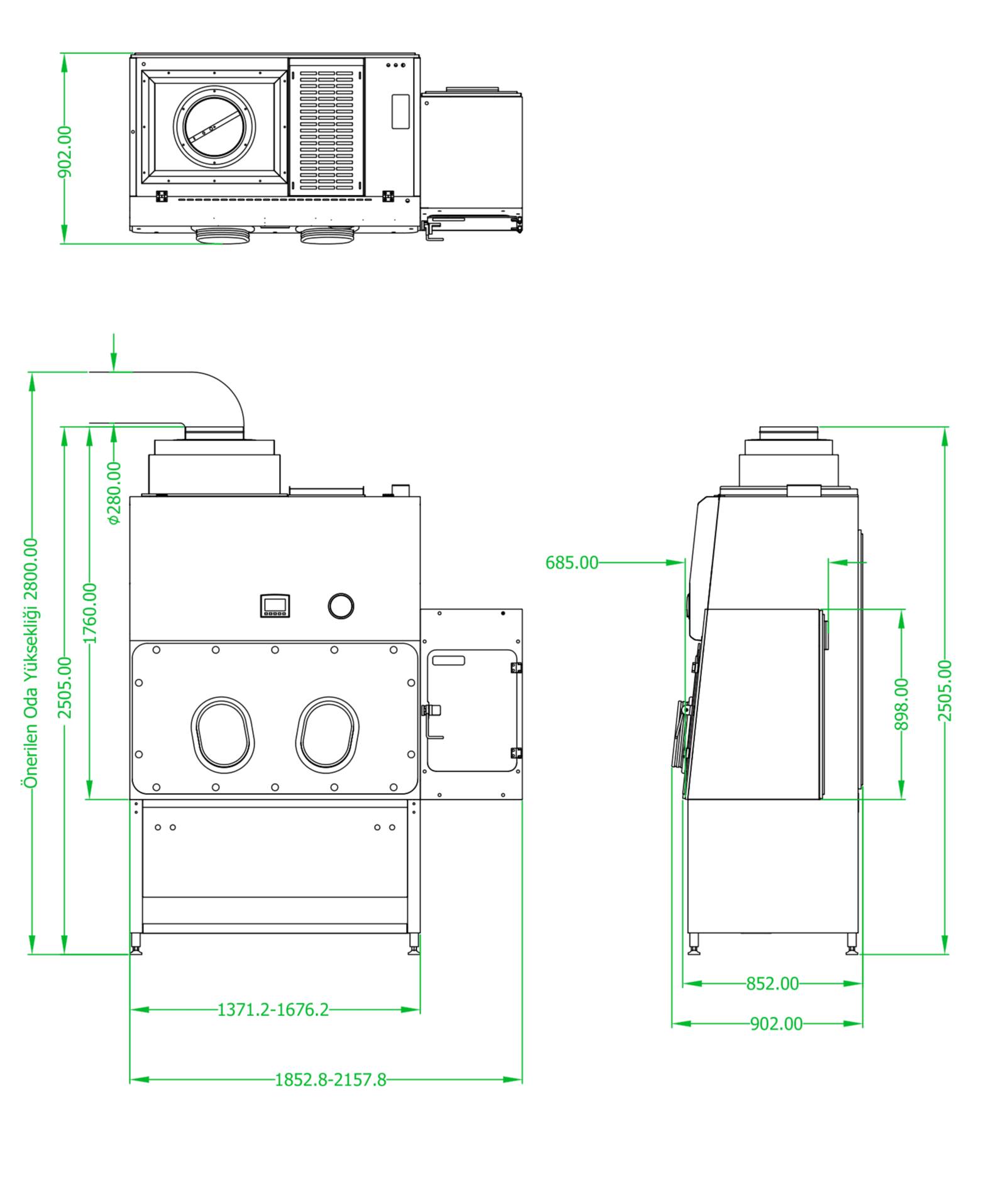

1371x902x1760

482x685x898

1371x805x745

840mm

0.30 m/s ± %20

700 <

HEPA, H14 %99.995, 0,3 μm

HEPA, H14 %99.995, 0,3 μm

EU4

304 Stainless Steel

316 Stainless Steel

2

< 65dB

≥750 Lux

1555x620x695

1676x902x1760

482x685x898

1676x805x745

840mm

900 <

0.30 m/s ± %20

HEPA, H14 %99.995, 0,3 μm

HEPA, H14 %99.995, 0,3 μm

EU4

304 Stainless Steel

316L Stainless Steel

< 65 dB

4

≥750 Lux

MSC-III Dimensions